Innovative technology for wine production lines

Mellow taste and understanding of life - this is the wonderful enjoyment that wine brings to people. If you desire a visual and taste feast, then we offer a new winemaking model that combines modern technological innovation with the essence of traditional craftsmanship - automation technology.

Our automation technology not only changes the traditional brewing method, but also promotes the progress of the entire industry. From grape picking to finished product filling, every step is completed by advanced automation equipment, achieving a double leap in production efficiency and product quality.

Automation helps wine making process

In this process, we use industry-leading automation equipment, such as efficient and accurate automatic picking machines and fully automatic packaging machines.

The automatic picking machine uses advanced visual recognition and robotic arms, and adopts a multi-sensor system to achieve high-precision grape picking, improving picking efficiency and reducing labor requirements.

The fully automatic packaging machine covers key aspects such as product filling, packaging and sealing, realizing full automation of material packaging and greatly reducing labor costs.

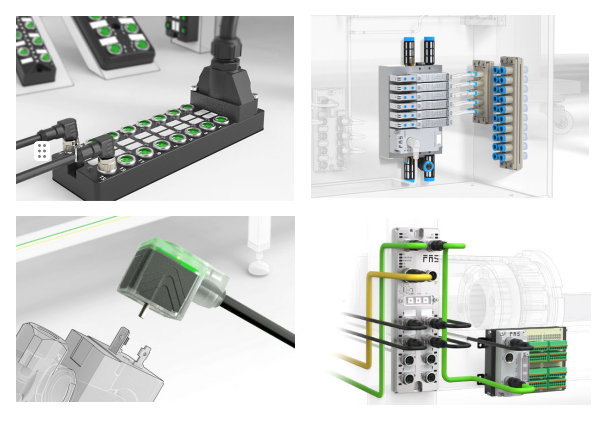

These devices are equipped with powerful industrial Ethernet module control solutions, making the internal wiring of the device simpler, data transmission smoother, and equipment maintenance more convenient.

Intelligent Application of Ethernet Technology

The industrial Ethernet module control solution centrally transmits sensor data to the central control system to achieve real-time monitoring and save additional equipment purchase costs.

Supporting remote monitoring and operation, the industrial Ethernet module control solution allows operators to remotely access and manage the system through the network, improving the flexibility and convenience of the system.

It is worth mentioning that the industrial Ethernet module has excellent protective performance and can effectively resist dust, water droplets and corrosion, and is suitable for use in various harsh environments. Its application makes production line layout and maintenance easier, further improving production efficiency and product quality.

Related Products